Efficiency, Reliability, and Longevity.

Recently, a customer asked me why we are such advocates for GAMIjector fuel injectors and lean-of-peak operation. I replied with three reasons why we recommend GAMIjector fuel injectors: Efficiency, Reliability, and Longevity.

Efficiency

The first and most obvious reason we recommend GAMIjector fuel injectors is for their efficiency – both in terms of operation and maintenance costs. You can save up to 40% on fuel when combined with advanced leaning techniques and over-square operation. Even the mere replacement of your standard fuel injectors with GAMIjector fuel injectors will save some fuel. In addition, properly designed fuel injectors deliver specific amounts of fuel to each individual cylinder, allowing for proper lean-of-peak operation, which in turn reduces fuel consumption and the occurrence of fouled spark plugs and other maintenance-related problems.

How Is This Even Possible?

GAMIjector fuel injectors are manufactured to much tighter tolerances and are designed to deliver specific amounts of fuel to each individual cylinder. This compensates for the fuel/air imbalance caused by the flawed design of the Continental and Lycoming induction and injection systems.

Inherent Flaw in Fundamental Design

The injection system of Continental and Lycoming engines is mechanical and not at all intelligent – quite different from the fuel injectors used in modern aircraft engines like Rotax’s lineup of four-stroke injection engines. This means that the fuel injectors are not electronically controlled to provide fuel intermittently to the intake manifold when required but continuously. This itself is not yet the problem solved by GAMIjector fuel injectors. The issue arises when fuel is carried downstream in the induction system, causing a fuel/air imbalance among the cylinders. This means that the cylinders upstream in the induction system are leaner than the cylinders downstream. The GAMIjector fuel injectors are not only carefully calibrated to much tighter tolerances than standard fuel injectors but are also designed to deliver specific amounts of fuel to each individual cylinder, solving the problem of the fundamental design flaw in the engine’s fuel/air system.

Fuel Savings

The majority of the fuel savings are not achieved with the installation of GAMIjector fuel injectors but because proper lean-of-peak operation is made possible due to the much more uniform fuel/air ratio in each individual cylinder. This means that each cylinder can have a similar air-to-fuel ratio at a given mixture setting. This makes it possible to operate all cylinders lean-of-peak at the same time without the problem of some cylinders being still rich-of-peak or flaming out because they are too lean. I have written dedicated blog posts about basic and advanced leaning techniques and the benefits of over-square operation but will repeat the main points in a nutshell once more.

Aircraft Engine Leaning

Before we can discuss leaning an aircraft engine, it’s essential to understand terms such as lean-of-peak (LOP), rich-of-peak (ROP) operation, and the stoichiometric ratio. The stoichiometric ratio is the quantitative relationship between the reactants and products of a specific reaction or chemical equation. In simpler terms, it’s the ratio at which all fuel is burned, and all oxygen is consumed. At this point, the exhaust gas temperature (EGT) reaches its maximum value (peak). For gasoline, this air-to-fuel ratio by mass is 14.7:1.

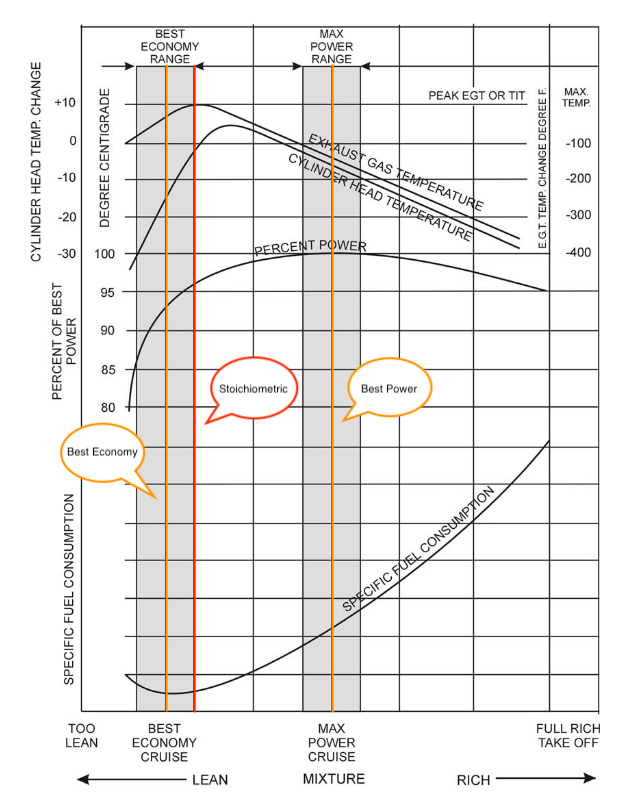

When the air-to-fuel ratio is leaner (excess air), we refer to it as lean-of-peak operation; when it’s richer (excess fuel), it’s known as rich-of-peak operation. This relationship, as illustrated in the graph from a Lycoming engine example, shows the stoichiometric ratio with a red vertical line at peak EGT, with lean mixture to the left and rich mixture to the right.

Cylinder Head Temperature and Internal Cylinder Pressure

While we won’t delve into the specifics of the “Red Box” and “Red Fin” concepts, it’s crucial to highlight the importance of cylinder head temperature (CHT) as an approximation for internal cylinder pressure (ICP).

Max. CHT & ICP is at about 40°F – 50°F ROP, which is often incorrectly stated as the best economy mixture setting in manuals, by flight instructors, and pilots.

The cylinder head temperature is our primary temperature limit in engine operation. We recommend the following CHT limits/ranges:

Continental Motors

Maximum CHT: 400°F

Optimal CHT: 330°F – 380°F

Lycoming

Maximum CHT: 420°F

Optimal CHT: 350°F – 400°F

Exhaust Gas Temperature

EGT limits are generally not critical and are usually not even included in aircraft engine manuals, except for turbocharged engines where turbine inlet temperature (TIT) limits are specified and must be adhered to.

It should now be evident that operating lean-of-peak can save fuel simply because the engines are operated with a leaner air-to-fuel ratio – less fuel for a given power setting. However, this is only part of the story. Observing the graph, we notice that the CHT curve on the left side of the maximum CHT value is steeper than on the right side. This implies that to reduce the CHT at any given power setting (usually below 70%), we can either slightly reduce the amount of fuel or significantly increase it to achieve the same reduction in CHT.

Over-Square Operation

There’s a common misconception among flight instructors and pilots regarding the over-square operation of an aircraft engine. Incorrect beliefs suggest that an aircraft engine should never be operated over-square, meaning the manifold pressure in InHg should never exceed the RPM divided by 100.

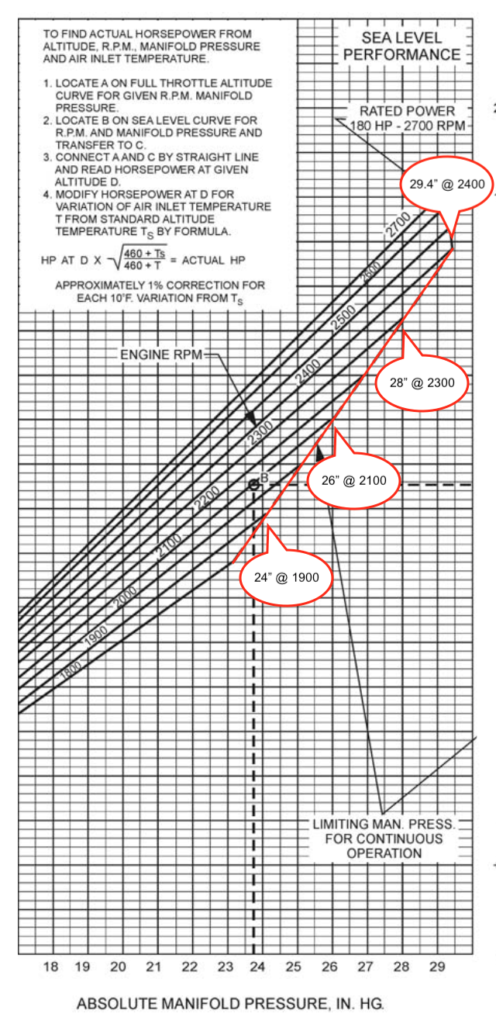

Examining, for example, the Sea Level and Altitude Performance chart for a Lycoming IO-360-B1A, you’ll notice that the limiting manifold pressure for continuous operation is well within the over-square operation regime. Far from being harmful, over-square operation offers several benefits (reduced noise and friction losses, improved propeller, volumetric, and combustion efficiency) and may be required for lean-of-peak operation.

Reliability

The second reason we recommend GAMIjector fuel injectors is for reliability. By operating our aircraft engines lean-of-peak for the majority of the time, we benefit from a cleaner combustion process. A leaner mixture burns much cleaner, thereby reducing the accumulation of deposits in the combustion chamber. Deposits tend to build up on cylinder heads, valves, piston crowns, and spark plugs, potentially leading to issues such as fouled spark plugs.

Many of us have had to abort takeoff because a magneto check revealed fouled spark plugs that could no longer be cleaned with aggressive leaning on the ground and required cleaning by an aircraft mechanic. Some have even encountered more severe issues, like pre-ignition events caused by (lead) deposits. While GAMIjector fuel injectors won’t resolve problems caused by extensive rich-of-peak operation, they enable us to operate our aircraft engines lean-of-peak, drastically reducing the likelihood of such issues.

Longevity

The third reason we recommend GAMIjector fuel injectors is longevity. As previously mentioned, cylinder head temperature serves as an approximation for internal cylinder pressure. It’s clear that a cleaner combustion process benefits your aircraft engine’s operation as well. So, how do GAMIjector fuel injectors improve your engine’s longevity? Operating your aircraft engine lean-of-peak reduces stress on the engine and helps keep the combustion chamber clean of (lead) deposits that could cause problems down the line. GAMIjector fuel injectors make it possible to operate our aircraft engines lean-of-peak, contributing to this benefit.

Conclusion

We are staunch advocates for GAMIjector fuel injectors because we believe in the value they add. We assert that any Continental and Lycoming powered aircraft should be equipped with engine monitor units and GAMIjector fuel injectors, provided they are fuel-injected. The only reason you might not equip your aircraft engine with GAMIjector fuel injectors is if your GAMI spread is already below 0.5 gallons per hour. We encourage checking out the in-flight test procedure to learn more about the GAMI spread.

In our view, there are three compelling reasons to recommend GAMIjector fuel injectors: Efficiency, Reliability, and Longevity. It may seem that all three reasons are based solely on lean-of-peak operation, and in a sense, that’s true. However, GAMIjector fuel injectors enable lean-of-peak operation in the first place, making these benefits interconnected and highly recommending their installation.

About Quest Aeronautics

Quest Aeronautics is a state-certified engineering office for aviation, dedicated to shaping the future of general aviation by providing innovative and cost-effective solutions to enhance aircraft performance and operations. With a focus on CS/FAR-23 and experimental/amateur-built (E/A-B) aircraft, Quest Aeronautics provides a range of services including flight testing, aircraft operations and maintenance consulting, high-quality aviation products, and tailored support for E/A-B projects. Collaborating with industry-leading partners, Quest Aeronautics is committed to delivering unparalleled support and expertise to individuals and organisations in the general aviation market.

About Author

Sebastian, the founder of Quest Aeronautics, is a driven and enthusiastic individual with a passion for aviation. Before delving into aviation, he gained valuable experience as a chemical process engineer and laboratory technician. Sebastian holds a Master of Science in Engineering and a commercial pilot licence, with several fixed-wing aircraft ratings under his belt. He has also completed an introduction course for fixed-wing performance and flying qualities flight testing at the National Test Pilot School in Mojave, CA and is compliance verification engineer for flight.