The Misconception Around Over-Square Operation.

Most pilots, even instructors, often fall prey to a widely spread myth about over-square operation. They’re mistakenly convinced that the manifold pressure in InHg should never exceed the RPM divided by 100. Many have heard cautionary tales of engines blowing up due to over-square operations. Consequently, we’ve been trained in a sequential method of control manipulation, namely throttle -> propeller -> mixture for power reduction and its reverse for power increase.

However, this age-old wisdom, like the misconceptions about leaning an aircraft engine, is due for some correction.

The Actual Facts on Over-Square Operation

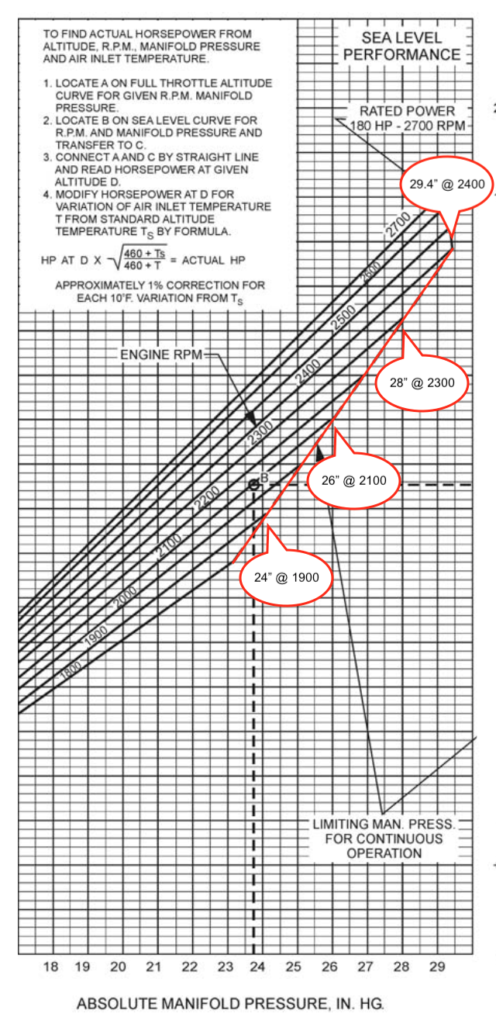

A deep dive into your aircraft engine operator’s manual will be quite revealing. The data suggests that limiting the manifold pressure for continuous operation still keeps us within the safe zones of over-square operation. Taking the Lycoming IO-360-B1A as an example (see below), it’s clear that this engine variant supports an over-square operation up to 5.4 inches. Other models vary in their allowances. Over-square operation is not an engine killer. Instead, it holds several advantages, even being essential for lean-of-peak (LOP) operation.

Key Benefits of Over-Square Operation

The practice of operating your engine over-square might raise eyebrows, but the benefits are manifold.

Reduced Noise

Slower propeller speeds significantly cut down the noise levels. The sonic shock waves at the propeller tips are minimised. The lower audible frequency produced is less jarring and gets easily muffled by ANR devices.

Minimised Frictional Losses

A decrease in RPM means fewer frictional losses in the engine and gear boxes. This not only improves efficiency but also reduces wear and tear.

Propeller Efficiency Boost

Propellers perform best at reduced RPM. This is precisely why some piston engines and turboprops use geared propellers. It’s an efficiency game.

Increased Volumetric Efficiency

A high manifold pressure combined with a lower RPM enhances the volumetric efficiency of the engine. This means better movement of the fuel and air charge in and out of the cylinders.

Enhanced Combustion Efficiency

A slower engine RPM allows more time for the combustion process. This results in fewer unburnt fuel residues, leading to cooler exhaust gas temperatures (EGTs). The transformation of chemical energy to kinetic energy is more efficient in this scenario.

Optimised Lean-Of-Peak Operation

Lean mixtures require more time for combustion. Traditional non-FADEC (full authority digital engine (or electronics) controlled) engines with magnetos lack control over combustion time. Here, reduced engine RPM becomes the saviour, ensuring complete combustion, especially in lean-of-peak operations.

Concluding Thoughts on Over-Square Operation

The aviation community has long been subjected to certain myths, and the doubts around over-square operation are prime examples. When delving deeper into the technicalities, the benefits of this operation style become clear. It’s time for pilots to shed outdated beliefs and embrace the actual advantages of over-square operation.

About Quest Aeronautics

Quest Aeronautics is a state-certified engineering office for aviation, dedicated to shaping the future of general aviation by providing innovative and cost-effective solutions to enhance aircraft performance and operations. With a focus on CS/FAR-23 and experimental/amateur-built (E/A-B) aircraft, Quest Aeronautics provides a range of services including flight testing, aircraft operations and maintenance consulting, high-quality aviation products, and tailored support for E/A-B projects. Collaborating with industry-leading partners, Quest Aeronautics is committed to delivering unparalleled support and expertise to individuals and organisations in the general aviation market.

About Author

Sebastian, the founder of Quest Aeronautics, is a driven and enthusiastic individual with a passion for aviation. Before delving into aviation, he gained valuable experience as a chemical process engineer and laboratory technician. Sebastian holds a Master of Science in Engineering and a commercial pilot licence, with several fixed-wing aircraft ratings under his belt. He has also completed an introduction course for fixed-wing performance and flying qualities flight testing at the National Test Pilot School in Mojave, CA and is compliance verification engineer for flight.