Aircraft Maintenance Rules: Set Clear Expectations With Your Maintenance Shop and Aircraft Mechanic

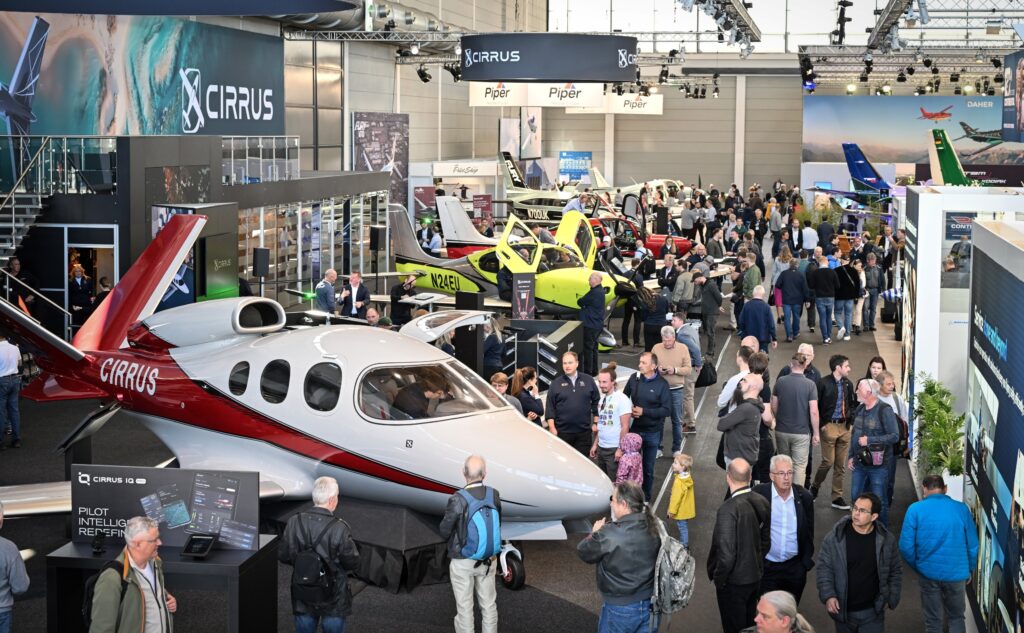

Why Defining Aircraft Maintenance Rules Matters for Every Pilot-Owner. Aircraft ownership comes with responsibility. One of the most important—but often overlooked—areas is setting clear rules with your maintenance shop and aircraft mechanic. Without clear expectations, confusion arises. Small misunderstandings can lead to major expenses, delays, or even safety issues. The solution? Define your aircraft maintenance […]