Abnormal Combustion Events Will Eventually Kill Your Aircraft Piston Engine.

Most aircraft piston engines still rely on technology from the 1960s and 70s. They lack modern sensors, knock detection, or advanced engine control units. This makes them vulnerable to detonation and pre-ignition—two forms of abnormal combustion that can destroy your engine if left unchecked.

Modern aircraft engines (like Rotax 915/916 iS engines) can detect and prevent these issues. Our Continental or Lycoming petrol engines can’t. That’s why understanding abnormal combustion is one of your best tools for protecting your engine and wallet.

Let’s explore how normal combustion works, what goes wrong during detonation or pre-ignition, and what you can do to prevent these engine killers.

Normal Combustion in Aircraft Piston Engines

Aircraft engines are internal combustion engines (ICEs). They burn an air-fuel mixture inside a combustion chamber to generate pressure, which pushes a piston down and turns the crankshaft.

In a typical four-stroke Otto engine, the air and fuel mix outside the combustion chamber—via a carburettor or fuel injection system—before entering the cylinder. The mixture is then compressed by the piston.

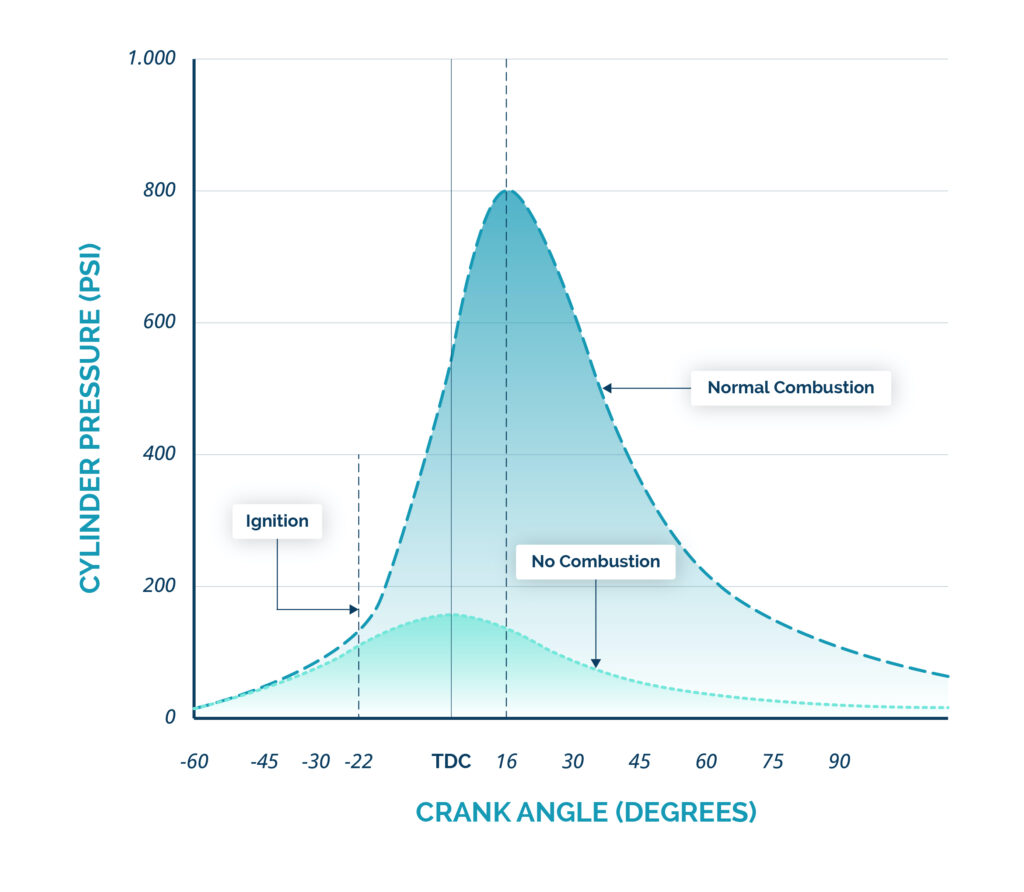

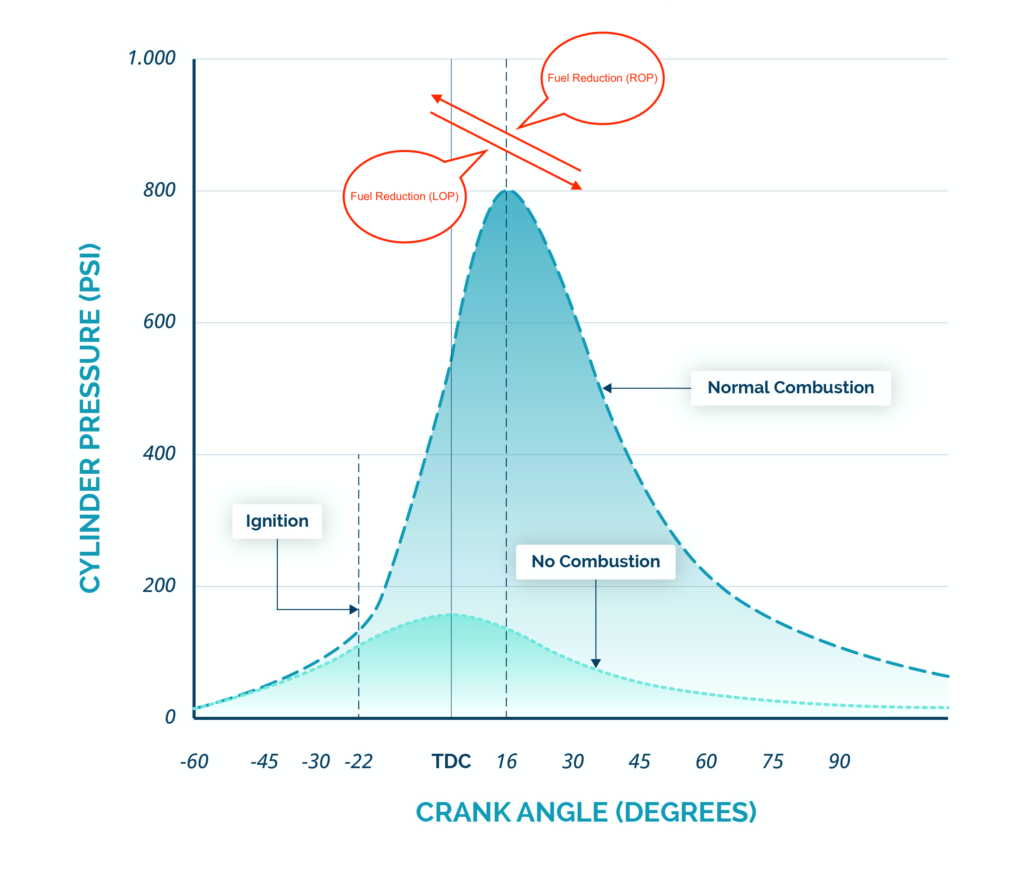

At just the right moment—usually 20° to 26° before top-dead centre (TDC)—two spark plugs ignite the mixture. This ensures the peak cylinder pressure occurs just after TDC, when the piston begins moving down. This timing maximises efficiency and power while minimising stress.

The combustion chamber includes the piston crown, cylinder walls, cylinder head, and valves. The shape and temperature of these components influence combustion.

In normal combustion, pressure builds up smoothly and predictably. But when abnormal combustion occurs, the pressure spikes unpredictably, threatening catastrophic engine damage.

What Is Abnormal Combustion?

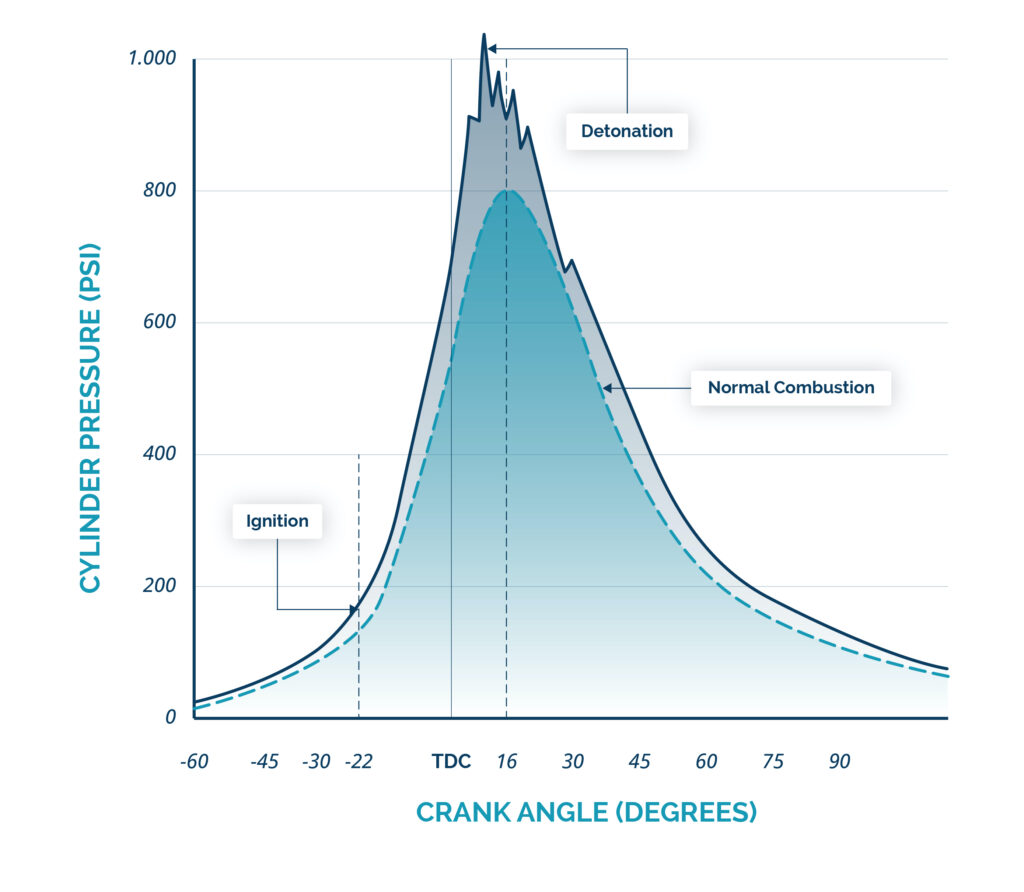

Abnormal combustion events disrupt the normal pressure curve inside the cylinder. The two most dangerous types are detonation and pre-ignition. Although separate phenomena, one can lead to the other—often with fatal consequences.

Detonation

Detonation is a spontaneous explosion of the end-gas (the last portion of unburned mixture). It usually occurs near or after TDC, caused by excessive pressure or temperature in the combustion chamber.

Rather than a controlled burn, detonation results in shock waves that hammer the piston crown and cylinder walls. The engine may sound like it’s pinging or knocking—though most pilots never hear it over the engine noise.

On an engine monitor, look for rising cylinder head temperatures (CHT) and falling exhaust gas temperatures (EGT).

Detonation can pit the piston crown—often described as “sandblasted.” If severe or sustained, it may also damage valves, rings, or even the spark plugs.

Worse yet, detonation can heat parts of the combustion chamber until they begin to glow—setting the stage for pre-ignition.

Pre-Ignition

Pre-ignition occurs when the air-fuel mixture ignites before the spark plug fires. This might be due to glowing carbon deposits, overheated spark plug tips, or a red-hot valve edge.

The result can be catastrophic. Pressure peaks too early—often before TDC—when the piston is still moving up. The explosion fights the piston’s motion, causing extreme pressure and heat.

Pre-ignition can destroy your engine in seconds. Melted pistons, fractured plugs, and broken rings are all common outcomes.

This isn’t just theory. If your piston has a melted hole, you’ve likely experienced pre-ignition. It’s often the final nail in the coffin after undetected or untreated detonation.

What Causes Detonation or Pre-Ignition in Aircraft Engines?

Detonation and pre-ignition don’t just happen. They are the result of specific, identifiable causes. Many are related to heat, pressure, and ignition timing.

Common Causes of Abnormal Combustion

- High compression and high cylinder temperatures

- Over-advanced ignition timing

- Hot spots from carbon deposits or glowing spark plug tips

- Wrong fuel grade or low octane rating

- Partially clogged injectors or imbalanced fuel distribution

- Poor cooling system performance (damaged baffles, failed seals)

- Wrong spark plug heat range (too hot or too cold)

- Oil contamination or combustion chamber debris

Engine Controls Affect Combustion Dynamics

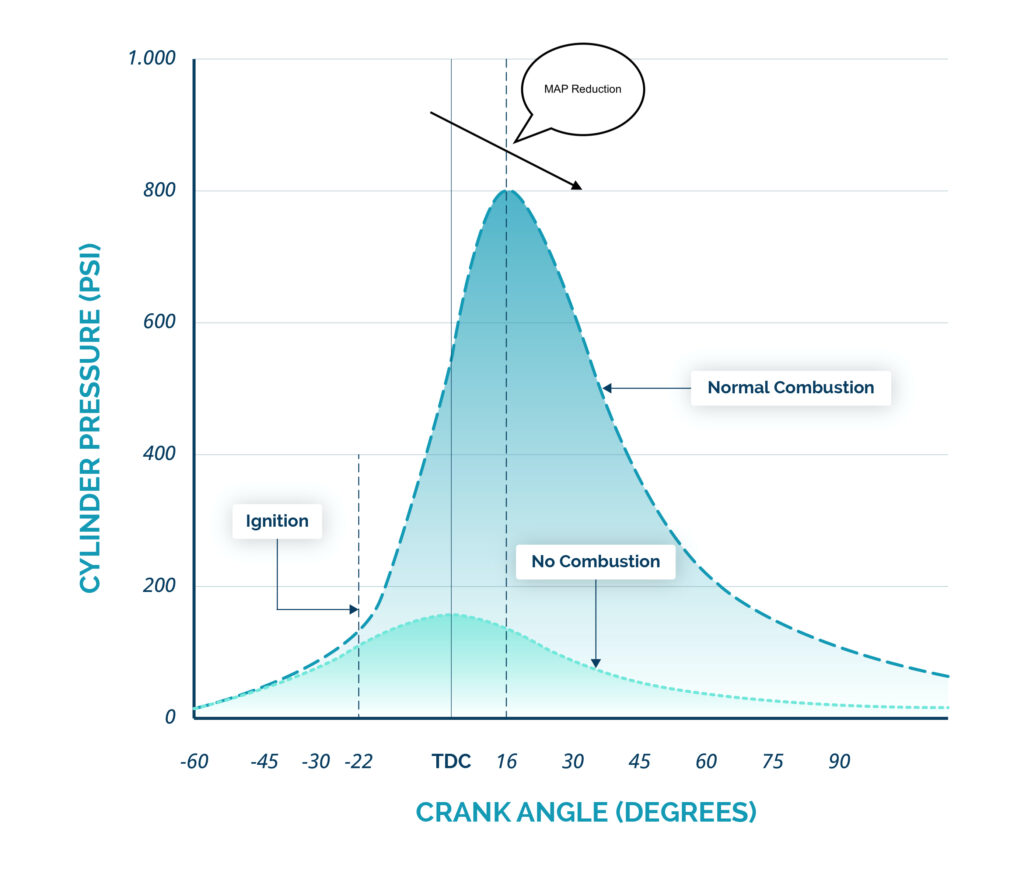

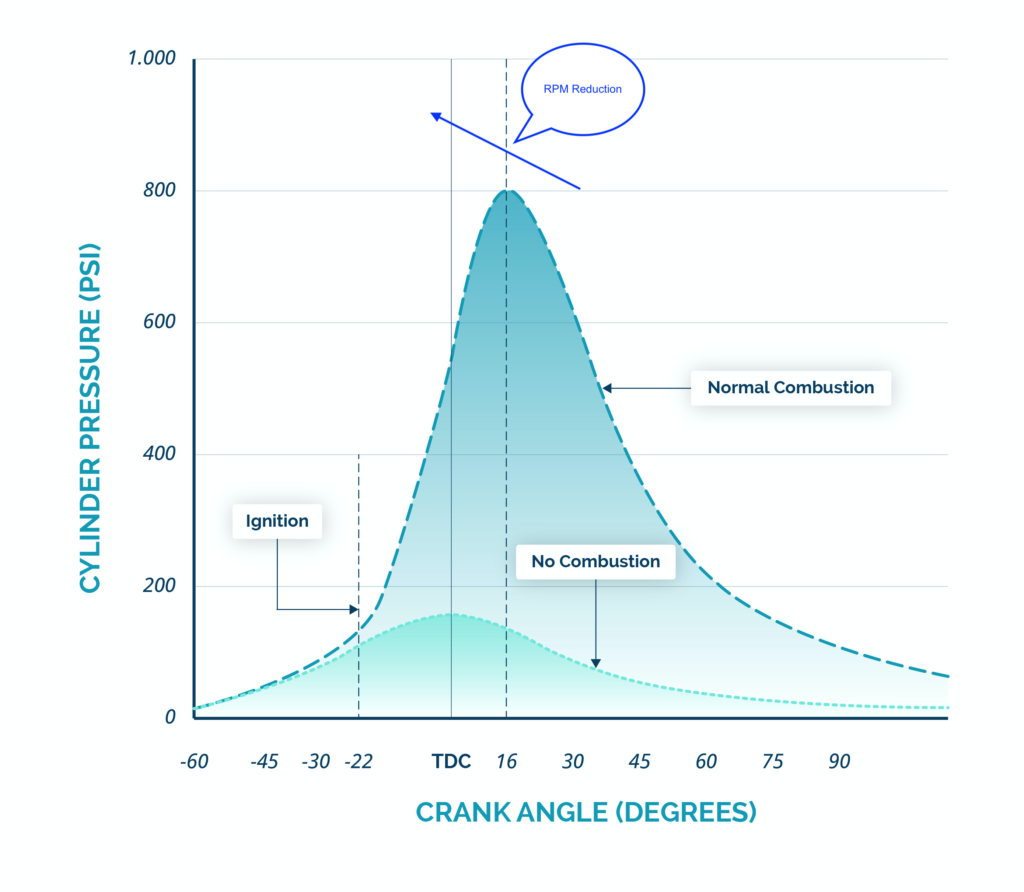

Throttle, propeller, and mixture control directly influence internal cylinder pressure and combustion timing. The following graphs illustrate how MAP, RPM, and mixture changes affect peak cylinder pressure (ICP) and its timing.

Effect of Throttle / MAP (Manifold Absolute Pressure)

Reducing MAP lowers peak ICP and shifts it to the right (later crank angle). Lower pressure and later timing reduce the risk of detonation.

Effect of Propeller RPM

Reducing RPM increases peak ICP and shifts it left (earlier crank angle). Higher pressure and earlier timing can increase detonation risk.

Effect of Mixture

ROP (Rich-of-Peak): Mixture reduction increases peak ICP and shifts it left (forward).

LOP (Lean-of-Peak): Mixture reduction decreases peak ICP and shifts it right (aft).

Understanding these relationships helps you manage combustion risks through smarter engine operation.

How to Prevent Abnormal Combustion in Aircraft Engines

Prevention comes down to two areas: maintenance and operation.

Maintain the Ignition, Fuel, and Cooling Systems

Ignition System

- Set and verify correct timing

- Replace spark plugs regularly

- Use correct heat range plugs

- Avoid lead fouling and carbon deposits

Fuel System

- Ensure correct full-power fuel flow

- Identify uneven fuel distribution (GAMI spread/lean range)

- Test injector balance after maintenance (In-Flight Test Procedures)

Cooling System

- Inspect baffles, seals, and airflow regularly

- Check for uneven cooling across cylinders

- Respect max CHT limits (typically 400°F for Continental, 420°F for Lycoming engines)

Operate with Intent and Precision

Fuel Quality

- Use approved, aviation-grade fuel

- Make sure to get the right quality (supplier, storage, etc.)

MAP, Propeller, and Mixture Control

- Take into account the aforementioned control inputs

Over-Square Operation

- Over-square is safe if within limits

Leaning

- Aggressively lean on the ground; Avoid prolonged idle at rich mixture

- Use advanced leaning techniques like Red Box/Fin concepts

Temperature

- Watch your temperatures

Carb Heat Use

- Use to prevent carb ice

- Monitor for excessive induction air temps

Protecting Your Aircraft Engine from Abnormal Combustion

Detonation and pre-ignition are destructive forms of abnormal combustion in aircraft piston engines. But they are not random. With proper maintenance and smart operation, abnormal combustion can be prevented.

Know the signs. Monitor your engine. Understand how your inputs affect combustion. And always respect your engine’s limits.

Want to learn more about how to lean effectively, evaluate your engine data, or extend engine life through better operation? We’re here to help.

At Quest Aeronautics, we equip pilot-owners with the tools, knowledge, and support to detect and prevent engine killers before it’s too late.

Stay informed. Stay proactive. And fly safe.

About Quest Aeronautics

Quest Aeronautics is a state-certified engineering office for aviation, dedicated to shaping the future of general aviation by providing innovative and cost-effective solutions to enhance aircraft performance and operations. With a focus on CS/FAR-23 and experimental/amateur-built (E/A-B) aircraft, Quest Aeronautics provides a range of services including flight testing, aircraft operations and maintenance consulting, high-quality aviation products, and tailored support for E/A-B projects. Collaborating with industry-leading partners, Quest Aeronautics is committed to delivering unparalleled support and expertise to individuals and organisations in the general aviation market.

About Author

Sebastian, the founder of Quest Aeronautics, is a driven and enthusiastic individual with a passion for aviation. Before delving into aviation, he gained valuable experience as a chemical process engineer and laboratory technician. Sebastian holds a Master of Science in Engineering and a commercial pilot licence, with several fixed-wing aircraft ratings under his belt. He has also completed an introduction course for fixed-wing performance and flying qualities flight testing at the National Test Pilot School in Mojave, CA and is compliance verification engineer for flight.