Aviation Insights for Serious Aircraft Owners

Evidence-Based Aviation Insights for Piston Aircraft Ownership

This section provides structured aviation insights focused on piston aircraft ownership, aircraft maintenance decision-making, aircraft engine operation, and professional airworthiness management. The content is written for owner-pilots operating Continental- and Lycoming-powered aircraft who want clarity, competence, and control — not folklore or forum advice.

Each article is designed to:

- Explain airworthiness management in practical terms

- Clarify aircraft engine operation principles

- Reduce maintenance uncertainty

- Provide structured aircraft ownership guidance

This is not aviation news.

It is operational insight.

Featured Post

In-Flight Test Procedures – DA40 with Lycoming IO-360-M1A

Why In-Flight Test Procedures Matter. In-flight test procedures are among the first things we ask clients to perform when we start working together or when they acquire a new (to them) aircraft. These tests quickly establish a baseline for your engine’s health. Completing the following in-flight test procedures takes about

Aviation Insights

Articles covering aircraft ownership, operations optimisation, maintenance decision-making, and independent advisory topics for private pilots and aircraft owners.

Aircraft Maintenance Rules: Set Clear Expectations With Your Maintenance Shop and Aircraft Mechanic

Why Defining Aircraft Maintenance Rules Matters for Every Pilot-Owner. Aircraft ownership comes with responsibility. One of the most important—but often overlooked—areas is setting clear rules

The Three Cs of Aircraft Maintenance: Competent, Communicative, Cooperative

Why Choosing the Right Maintenance Shop Is Essential for Every Pilot-Owner. Aircraft maintenance can either protect your investment—or drain your wallet and confidence. It depends

🚀 Why We Rebranded: From Pilot-Owner Academy to the Pilot-Owner Accelerator

Why the Change to Pilot-Owner Accelerator Matters and How it Helps You Fly Smarter, Safer, and More Cost-Effectively. The original idea for the Pilot-Owner Academy

Engine Killers – Abnormal Combustion Events in Aircraft Piston Engines

Abnormal Combustion Events Will Eventually Kill Your Aircraft Piston Engine. Most aircraft piston engines still rely on technology from the 1960s and 70s. They lack

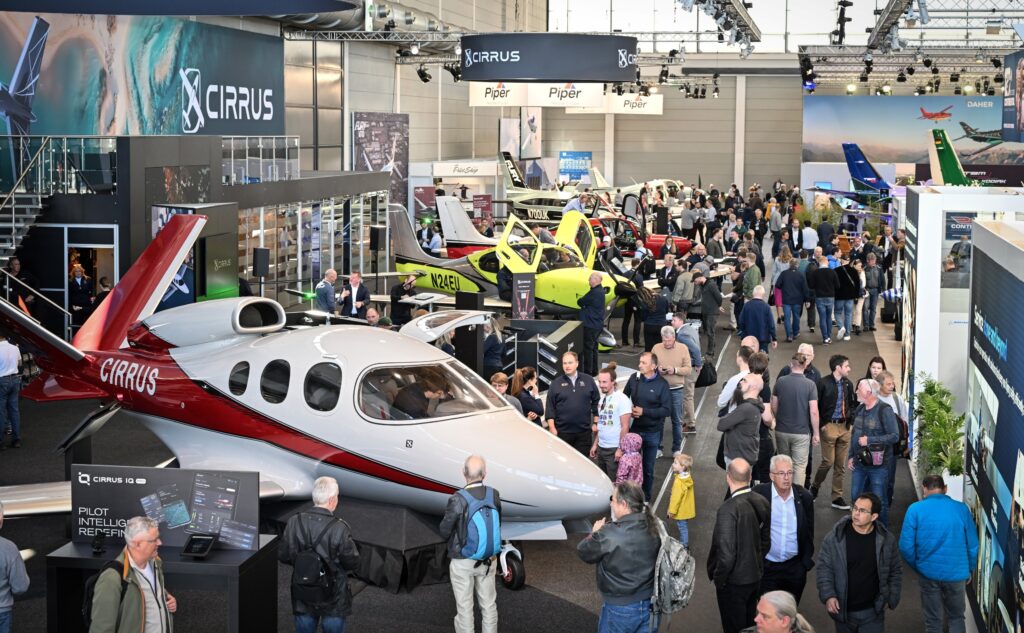

AERO 2025 Recap – Quest Aeronautics Is Fully Booked for This Quarter

Discover why so many pilot-owners are joining the Pilot-Owner Academy—and how you can secure your spot next. AERO 2025 was a major success. We connected

Quest Aeronautics Will Be at AERO 2025 for Exclusive Live Events

Join us for a live event at AERO 2025 and get a chance to book a complimentary 60-minute strategy session. We’re excited to announce that

Receive selected insights, strategic perspectives, and practical guidance directly in your inbox — no marketing noise, just relevant aviation topics.